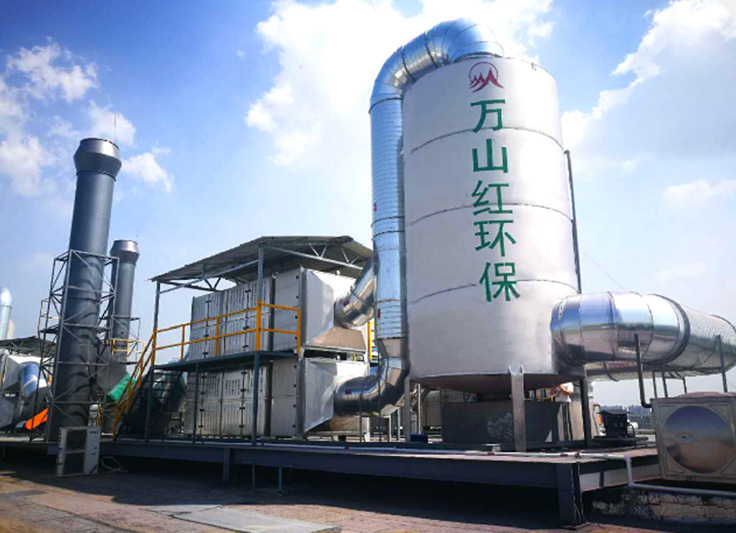

How Are Industrial Waste Gases Treated?

Release time: 2024-10-17

Industrial waste gases pose significant environmental and health risks due to the presence of harmful pollutants. To mitigate these risks, various treatment methods have been developed to reduce emissions and improve air quality. This article explores the key methods used in the treatment of industrial waste gases, detailing their mechanisms, applications, and benefits.

Understanding Industrial Waste Gases

Industrial waste gases are emissions produced during manufacturing, processing, or energy generation. These gases can contain harmful substances, including:

Volatile Organic Compounds (VOCs)

Nitrogen Oxides (NOx)

Sulfur Oxides (SOx)

Carbon Monoxide (CO)

Particulate Matter (PM)

The treatment of these waste gases is essential for regulatory compliance, environmental protection, and public health.

Key Methods of Industrial Waste Gas Treatment

1. Absorption

Absorption is a widely used method that involves the transfer of gaseous pollutants into a liquid absorbent. Here’s how it works:

Mechanism: The waste gas is passed through a liquid medium, where specific gases dissolve. Common absorbents include water or chemical solutions tailored to capture specific pollutants (e.g., sodium hydroxide for sulfur dioxide).

Applications: This method is effective for removing acidic gases and other water-soluble compounds.

Benefits: It reduces the concentration of harmful gases before they are released into the atmosphere and can often allow for the recovery of valuable byproducts.

2. Adsorption

Adsorption involves capturing pollutants on the surface of solid materials. Here’s a closer look:

Mechanism: The waste gas flows through a bed of adsorbent materials, such as activated carbon or zeolites. Pollutants adhere to the surface due to physical or chemical interactions.

Applications: This method is particularly effective for VOCs and other organic compounds.

Benefits: Adsorption systems can be designed for regeneration, allowing for the reuse of the adsorbent material, thus reducing operational costs.

3. Combustion

Combustion is a method that incinerates waste gases at high temperatures:

Mechanism: The waste gases are ignited in a controlled environment, converting harmful compounds into less harmful substances, mainly carbon dioxide and water vapor.

Applications: Commonly used for treating volatile organic compounds and hazardous air pollutants.

Benefits: This method effectively reduces the volume of harmful emissions, ensuring that pollutants are transformed into safer substances before being released.

4. Chemical Treatment

Chemical treatment employs chemical reactions to neutralize or transform pollutants:

Mechanism: Harmful gases are treated with reagents that react to form non-toxic byproducts. For example, alkaline solutions can neutralize acidic gases.

Applications: This method is often used for specific industrial emissions, such as acid gases from petrochemical operations.

Benefits: Chemical treatment can be tailored to specific pollutants and is often efficient in reducing concentrations of hazardous substances.

5. Biological Treatment

Biological treatment leverages microorganisms to break down organic pollutants:

Mechanism: Waste gases are passed through a bioreactor where microorganisms metabolize the contaminants, converting them into harmless byproducts.

Applications: Effective for treating VOCs and other biodegradable organic compounds.

Benefits: This method is environmentally friendly and can often achieve high levels of pollutant removal while minimizing chemical usage.

6. Membrane Separation

Membrane separation technology utilizes selective membranes to separate pollutants from waste gases:

Mechanism: Waste gases are passed through membranes that selectively allow certain molecules to pass while retaining others. This method can separate gases like carbon dioxide from nitrogen.

Applications: Useful for CO2 capture and in processes requiring the separation of specific gases.

Benefits: Membrane technology is energy-efficient and can operate continuously, providing a reliable method for gas separation.

Conclusion

The treatment of industrial waste gases is essential for minimizing environmental impact and safeguarding public health. Various methods, including absorption, adsorption, combustion, chemical treatment, biological treatment, and membrane separation, each offer unique advantages and applications. By investing in effective waste gas treatment solutions, industries can not only comply with regulations but also contribute to a cleaner, healthier environment for all. Embracing these technologies will be crucial as the world moves toward more sustainable industrial practices.