Product Name

Waste gas treatment in the printing and coating industry

Product Description

Product Name

The printing and coating industry is a key area for industrial volatile organic compounds (VOCs) and particulate matter pollution. Its waste gas is characterized by complex composition, flammability and explosiveness, and high treatment difficulty. The following is a systematic analysis from aspects such as waste gas characteristics, treatment technologies, typical processes, and policy trends, and targeted solutions are provided:

I Core Characteristics of Industry Waste Gas

(1) Waste Gas from the Printing Industry Source: Ink preparation, printing process (offset printing, gravure printing, flexographic printing), drying / laminating process, equipment cleaning. Composition: VOCs: Toluene, xylene, ethyl acetate, ethanol, methyl ethyl ketone, isopropyl alcohol, etc. (solvent – based inks have a high proportion). Particulate Matter: Ink particles, paper fiber dust (more obvious in letterpress printing).

(2) Exhaust Gas from the Painting Industry Source: Spraying (atomization of paint and coating), leveling (solvent evaporation), drying (high-temperature evaporation), pre-treatment (degreasing and volatilization).

Composition: VOCs: Xylene, butyl acetate, methyl isobutyl ketone (MIBK), cyclohexanone, styrene, etc. Particulate Matter: Paint mist (resin and pigment particles, particle size 1 – 100μm), grinding dust. Other Pollutants: Some contain cyanides (electrophoresis process), heavy metals (such as chromates).

Features: The waste gas in the spraying workshop has high humidity and contains viscous paint mist, which can easily clog the treatment equipment; The waste gas from drying has high temperature and high concentration (the VOCs concentration can reach 2000 – 5000mg/m³), and has a high risk of explosion and fire.

II. Core Processing Technologies and Application Scenarios

▌Pretreatment technology: Removal of particulate matter and viscous pollutants

| Technology, | principle | application scenario | key parameters |

|---|---|---|---|

| Water curtain / Water cyclone defogging | The water curtain captures paint mist particles, forming wastewater. | Pre – treatment at the front – end of automotive spraying and furniture painting lines | The paint mist removal rate is > 90%, and wastewater treatment facilities need to be provided. |

| Dry filtration | Fiberglass wool / non-woven fabric intercepts particulate matter | Printing and drying line, hardware spraying line | The filtration efficiency is > 95% and the pressure drop is < 500 Pa. |

| Electrostatic demisting | The high – voltage electric field adsorbs charged particles | High-concentration paint mist scenarios (such as coil coating) | Low energy consumption, and the processed air volume can reach 100,000 m³/h |

▌VOCs Treatment Technologies: Selection Based on Concentration Levels

(1) Low-concentration waste gas (<1000mg/m³)

| technology | Principle | Typical process | Applicable scenarios |

|---|---|---|---|

| Activated carbon adsorption | Microporous adsorption of VOCs, regeneration or replacement after saturation | Activated carbon box + fan | Small and medium-sized printing workshops, furniture touch-up paint rooms |

| Biological treatment | Microbial degradation of water – soluble VOCs | Biological filter / biological trickling filter tower | Water – based ink printing, food packaging printing |

| Photocatalytic oxidation | UV light + catalyst decomposition of VOCs | Photo – oxygen catalytic equipment + activated carbon | Laboratory spraying, treatment of low-concentration odors |

(2)Medium and high concentration waste gas (500 – 5000mg/m³)

| technology | Principle | Typical process | Applicable scenarios |

|---|---|---|---|

| Catalytic combustion (RCO) | Catalysts oxidize VOCs to CO₂ + H₂O at low temperatures | Activated carbon adsorption + catalytic combustion integrated machine | Printing and drying line, automotive repair painting |

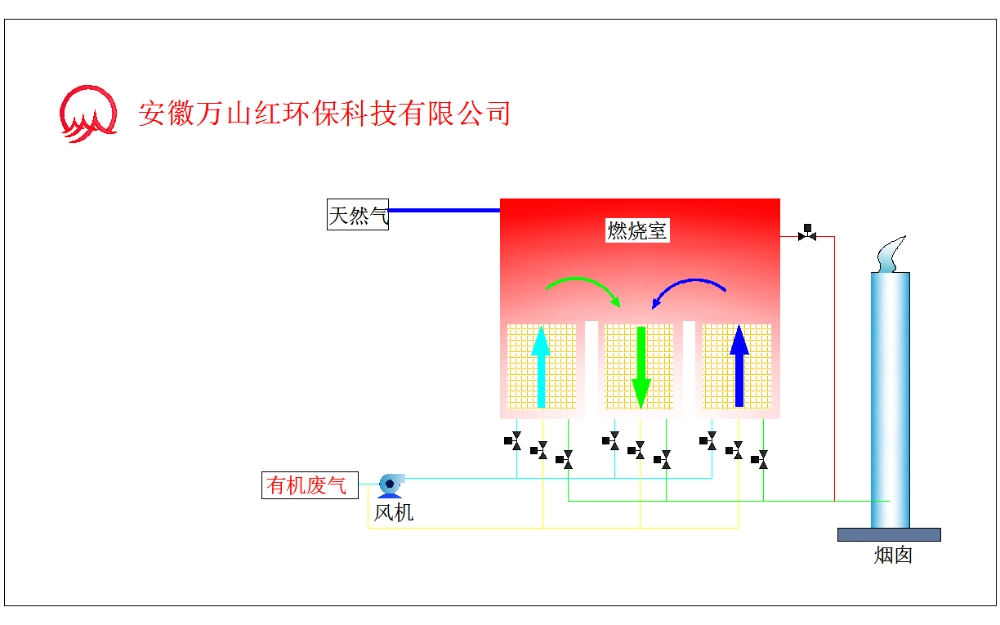

| Regenerative Thermal Oxidizer (RTO) | High – temperature incineration + heat recovery of regenerator | Zeolite Rotating Wheel Concentration + RTO | Large printing enterprises (web-fed printing), container painting |

III. Typical technological processes

(1) Printing enterprises (solvent-based inks, medium scale)

Technological process:Gas collection hood (collection efficiency ≥ 90%) → Primary – effect filtration (removal of ink particles) → Activated carbon adsorption box (2 sets in rotation, off – line regeneration) → Fan → Discharge up to standard (VOCs concentration < 50mg/m³).

(2) Automobile spraying line (solvent-based paint)

Technological process:Spray booth (water swirl to remove paint mist, wastewater enters the flocculation tank) → Drying room (top air supply + side suction) → High – efficiency filter box (glass fiber wool) → RTO incinerator (temperature 800℃, residence time > 2s) → Chimney (waste heat is used to preheat fresh air).

IV. Industry Pain Points and Solutions

- Risk Control of Flammable and Explosive Substances ◦

- Measures:

- Use anti-static materials for exhaust gas pipelines, and install flame arresters and explosion relief discs;

- Configure online VOCs concentration monitoring for RTO/RCO equipment. When the concentration exceeds 25% of the lower explosive limit (LEL), automatically dilute with fresh air.

- Measures:

- The treatment cost of waste gas with low concentration and high volume is high.

- Measures:

- Adopt the zeolite rotary concentrator technology (with a concentration multiple of 10 – 20 times) to convert low – concentration waste gas into medium – high concentration, reducing the combustion energy consumption.

- Small – scale enterprises can choose activated carbon adsorption + moving bed regeneration (a third – party professional team replaces the saturated carbon regularly) to avoid building their own regeneration systems.

- Measures:

- Paint mist adhesion equipment ◦

- Measures:

- Set up multi – stage filtration (primary + medium – efficiency + high – efficiency) at the front end of the painting line, and replace the filter cotton regularly (it is recommended to replace it once every two weeks);

- Use anti – adhesion coating activated carbon or ceramic catalysts to reduce the risk of paint mist blockage.

- Measures:

.png) Inquire

Now

Inquire

Now